Tig Welding Patterns

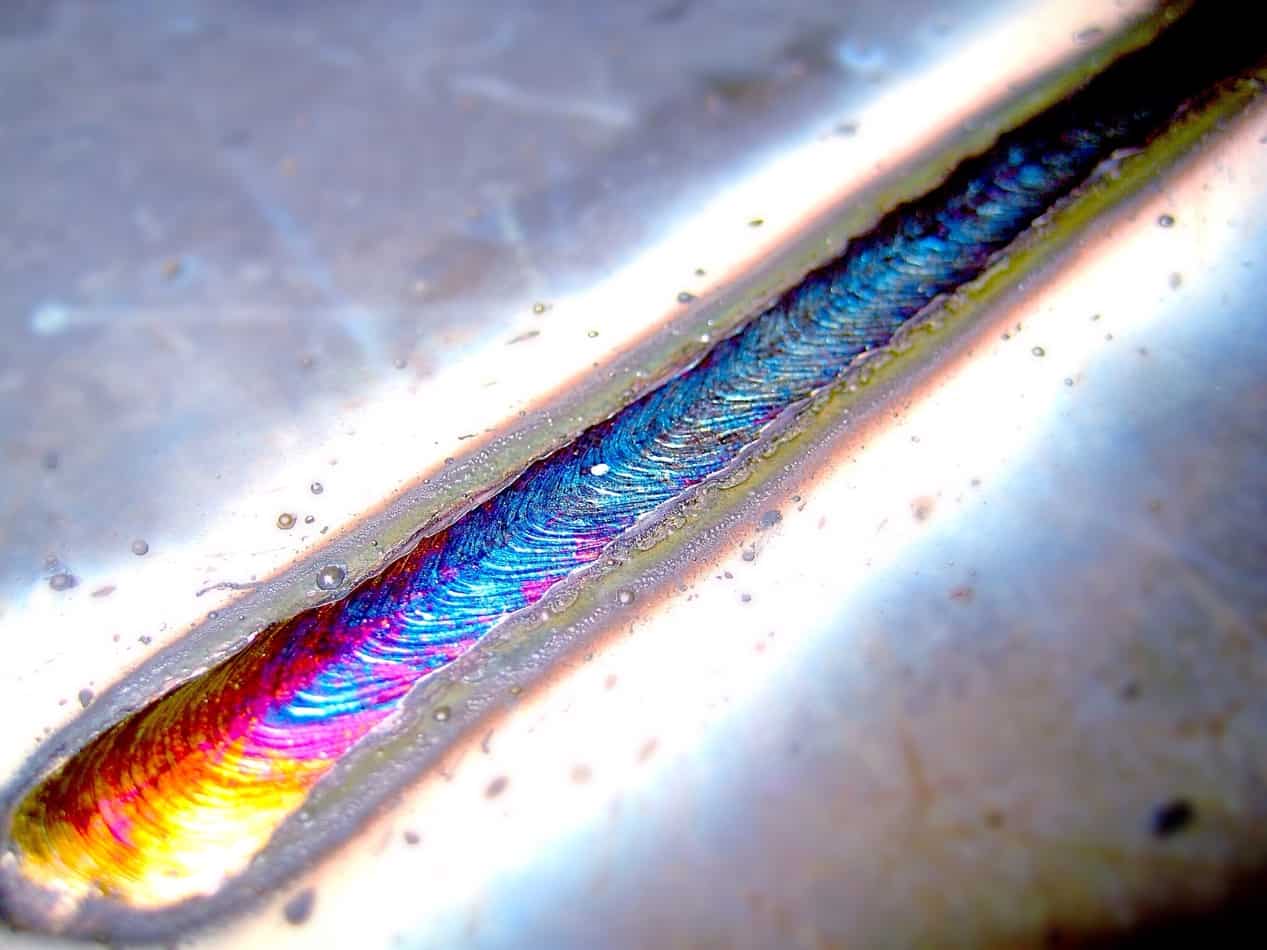

Tig Welding Patterns - It simply involves dragging the welding wire straight across the seam without any intricate weaving or movement. Types and polarity of welding power supply. Web the five main factors that influence a colorful tig weld are: The effect of joint angle on corrosion resistance was obvious. Web these are eighteen tips and techniques to elevate your tig welding game or give you a good start on your tig welding journey. Updated and improved eastwood tig 200. Web tig welding is probably he most complicated type of welding there is, and for a beginner the shear number of variable can be a bit confusing. We’ll hit on the latter in a bit, but right now let’s focus on the former. The guide is split into specific areas of welding and cutting and designed to give an understanding of these areas. Tig welding is a manual welding process that requires the welder to use two hands to weld. Besides cleanliness, tig welding is often used when aesthetics are required, and the most common appearance you might have noticed is the stacked dime. Bad welds, and the story your weld tells. Although not the most pleasing pattern to the eye, it gets the job done by enhancing the strength of the weld. It simply involves dragging the welding wire straight across the seam without any intricate weaving or movement. The process uses an inert gas, usually argon, to shield the welding area from atmospheric contamination. These automatically control gas and water flow when welding begins and ends. The effect of joint angle on corrosion resistance was obvious. Updated and improved eastwood tig 200. Also, it's more precise and can be used with all types of metals. This guide is designed to provide helpful information relating to the electric arc welding and cutting process. Web what does good welding look like? Tig pinpoints the heat much better and a foot control is often used to regulate amperage. Below is a break down on all the different areas with some “numbers” to help you get started. The tungsten electrode then creates an electric arc that melts the workpiece, forming a weld pool. This guide is. Updated and improved eastwood tig 200. Tig welding process was adopted, with argon as the shielding gas and 316l welding wire as the filler wire,. Web these are eighteen tips and techniques to elevate your tig welding game or give you a good start on your tig welding journey. Learn tig welding tips, best practices, and tricks of the trade. Besides cleanliness, tig welding is often used when aesthetics are required, and the most common appearance you might have noticed is the stacked dime. It simply involves dragging the welding wire straight across the seam without any intricate weaving or movement. Let this article be your guide to creating colorful tig welds. Tungsten inert gas (tig) welding can utilize either. These automatically control gas and water flow when welding begins and ends. It simply involves dragging the welding wire straight across the seam without any intricate weaving or movement. Tig pinpoints the heat much better and a foot control is often used to regulate amperage. Tig welds are often used to build fences, and bike frames, attach fenders, repair pipes,. Web tig welding is probably he most complicated type of welding there is, and for a beginner the shear number of variable can be a bit confusing. We’ll hit on the latter in a bit, but right now let’s focus on the former. Web with the ability to join metals like aluminum, titanium, stainless steel, and other exotic alloys, it. We’ll hit on the latter in a bit, but right now let’s focus on the former. Most people assume that all weaved tig welds are “walked.” it’s by far the more popular method, and for good reason. Tig welding process was adopted, with argon as the shielding gas and 316l welding wire as the filler wire,. Also, it's more precise. Tig welding process was adopted, with argon as the shielding gas and 316l welding wire as the filler wire,. Web there are basically two ways to weave a tig weld: Tig pinpoints the heat much better and a foot control is often used to regulate amperage. Web what does good welding look like? Tig welds are often used to build. In this article, we will look at easy tig welding tips and tricks to help in your path to becoming a professional welder! These automatically control gas and water flow when welding begins and ends. Besides cleanliness, tig welding is often used when aesthetics are required, and the most common appearance you might have noticed is the stacked dime. The. Walking the cup and freehand. This guide is designed to provide helpful information relating to the electric arc welding and cutting process. Tig pinpoints the heat much better and a foot control is often used to regulate amperage. It requires shielding gas, mostly pure argon or argon mixed with helium. Learn tig welding tips, best practices, and tricks of the. Also, it's more precise and can be used with all types of metals. Tig welding is a manual welding process that requires the welder to use two hands to weld. Below is a break down on all the different areas with some “numbers” to help you get started. Besides cleanliness, tig welding is often used when aesthetics are required, and. Learn tig welding tips, best practices, and tricks of the trade for beginning and intermediate welders from metalworker ron covell. Web we sat down and compiled the 4 most important things every tig welder should know. Tig pinpoints the heat much better and a foot control is often used to regulate amperage. Web the five main factors that influence a colorful tig weld are: This guide is designed to provide helpful information relating to the electric arc welding and cutting process. Most people assume that all weaved tig welds are “walked.” it’s by far the more popular method, and for good reason. But, welding aluminum may sometimes require a balled, hemispherical tungsten tip. Tig welding is a manual welding process that requires the welder to use two hands to weld. Types and polarity of welding power supply. Web tig welding is quite popular because it produces higher quality welds than mig welding offers. These automatically control gas and water flow when welding begins and ends. The process uses an inert gas, usually argon, to shield the welding area from atmospheric contamination. Below is a break down on all the different areas with some “numbers” to help you get started. Also, it's more precise and can be used with all types of metals. Besides cleanliness, tig welding is often used when aesthetics are required, and the most common appearance you might have noticed is the stacked dime. You can join steel, aluminum, copper, and stainless steel with the tig welding process in.Tig Welding Colors EXPLAINED YouTube

Welding For Artists What Welding Method Should You Learn? WeldingMania

MIG vs TIG Welding Types, Materials, and Applications A Guide

Tig Weld Patterns Pattern.rjuuc.edu.np

welding art projects for beginners Weldingart Welding art, Welding

"The art of Welding" weavewednesday tig weldporn weldlicious

How To Make A Colorful TIG Weld The Complete Guide Welding Mastermind

best tig welding around the world YouTube

ultimate tig weld Google Search Welding Cart, Welding Rigs, Mig

Tig weave Welding, Welding art, Tig welding

Web Guide To Tig Welding.

The Tungsten Electrode Then Creates An Electric Arc That Melts The Workpiece, Forming A Weld Pool.

What Separates Tig Welding From Most Other Welding Processe S Is The.

Web Tig Welding Process Parameters 1.

Related Post: