Gyroid Infill Pattern

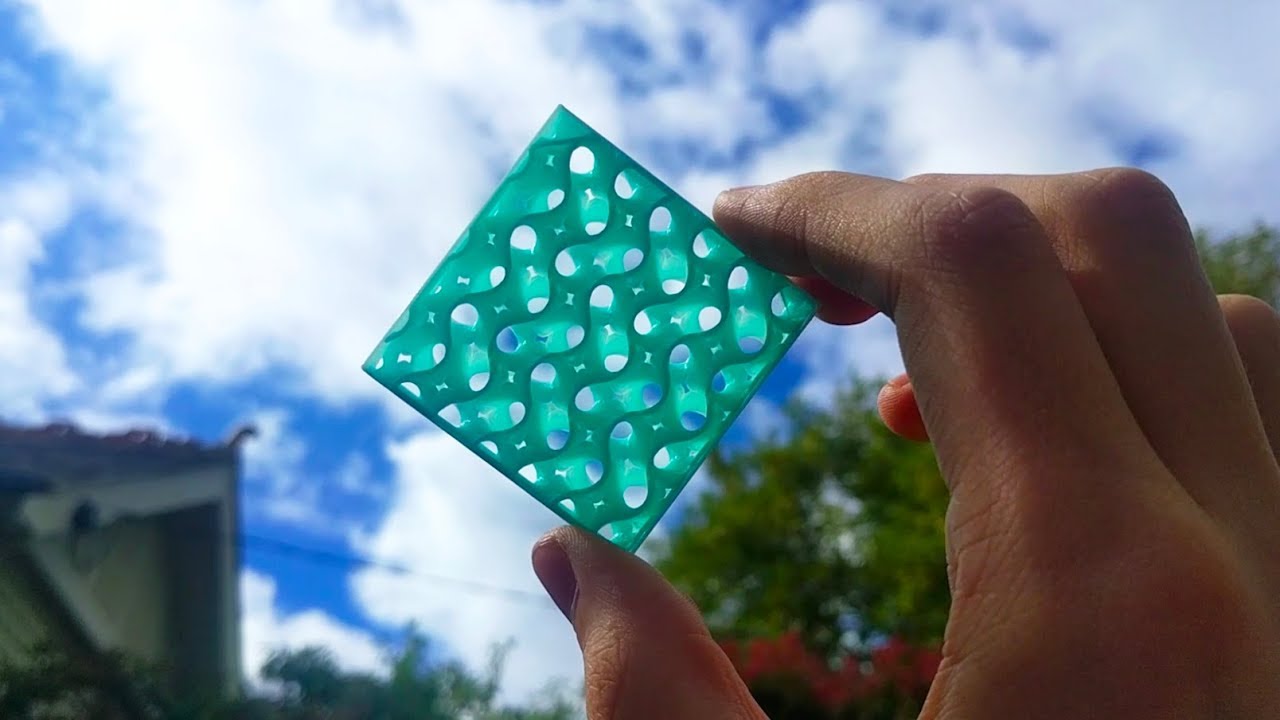

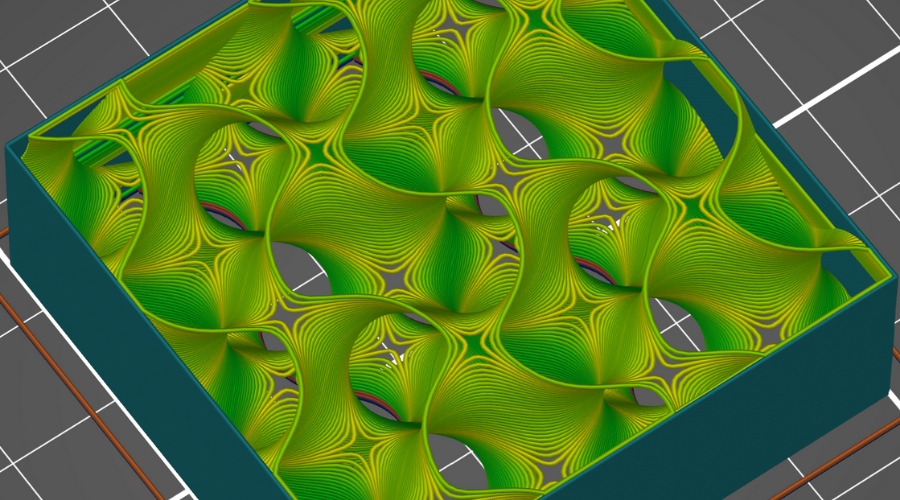

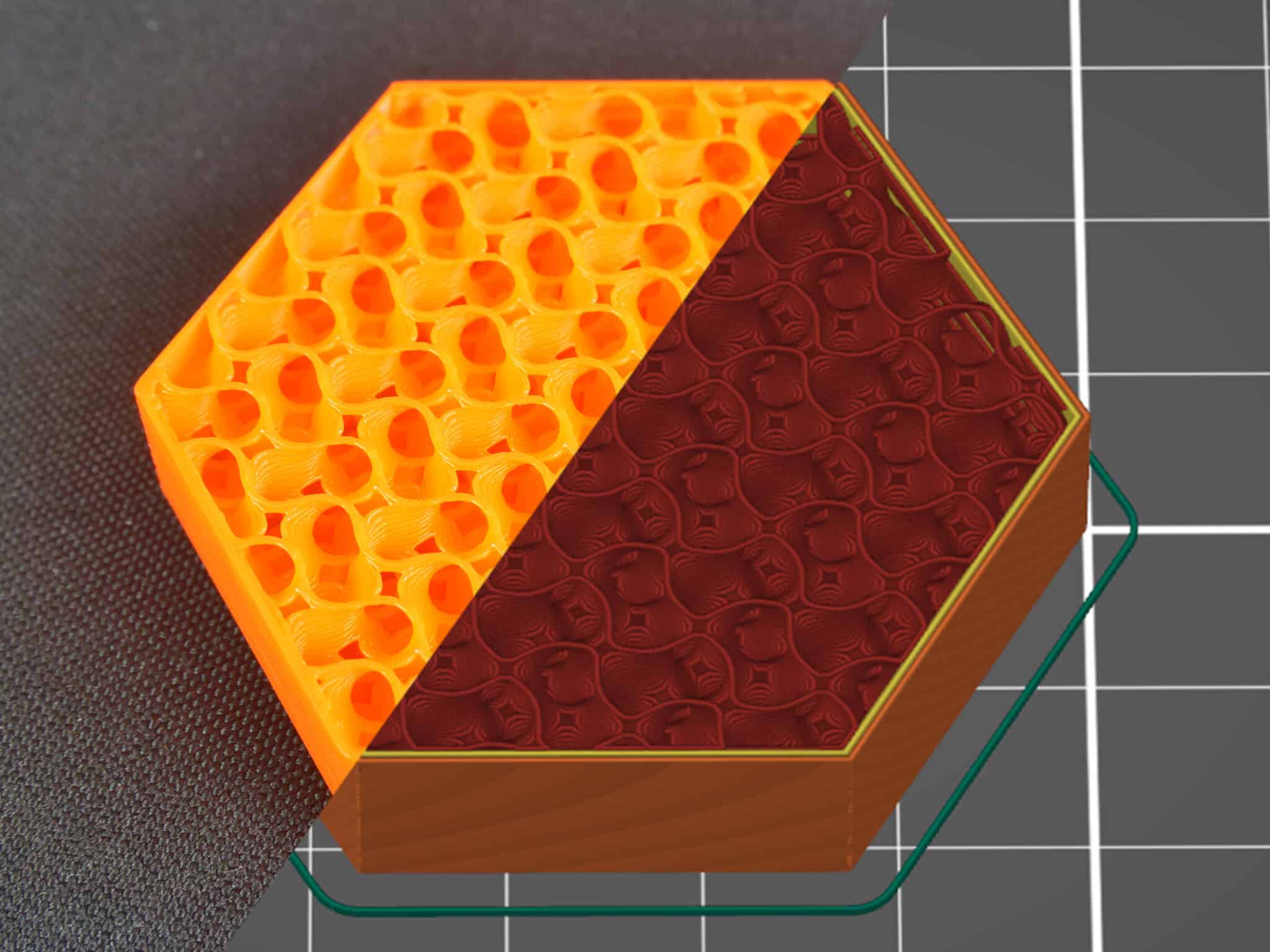

Gyroid Infill Pattern - Web the advantages of gyroid infill over the tested infill types are: Web an infill pattern can be both aesthetically pleasing and super strong. Let's explore the advantages of this cool new infill pattern and why you'll never use any other infill again. Uniform in all orientations), meaning that is very suitable for flexible prints. Web infill pattern refers to the internal structure of the 3d printed part. The continuous, interconnected channels enable efficient material distribution, reducing the chances of clogs or inconsistent extrusion. Web gyroid infill patterns can significantly improve your 3d prints by removing the necessity of configuring infill orientation to support your model. Web gyroid infill alternates between horizontal and vertical directions, meaning there are gaps in the z direction. The gyroid is our favorite and one of the best infills. Learn about the gyroid infill pattern and its purposes, properties and advantages and disadvantages for your 3d printing applications. Web gyroid infill refers to when a 3d printed object integrates a gyroid pattern as its internal geometry. Web gyroid has the strongest strength distribution in all directions, meaning no other infill pattern is as strong at resisting forces in all directions both vertically and horizontally. A lot of people love the gyroid pattern because it also looks beautiful, especially when you use transparent filaments because you can see the internal geometry. Web choosing a strong infill pattern is normally relatively easy. In the xy direction it looks like thousands of springs. Web the gyroid infill pattern is one of the most popular options in cura in recent years, beloved by 3d printing enthusiasts for its aesthetic look on 3d prints. The gyroid is our favorite and one of the best infills. You can also change top and bottom layer infill types to get some interesting results. Web gyroid infill patterns can significantly improve your 3d prints by removing the necessity of configuring infill orientation to support your model. High shear strength, and ; You can also change top and bottom layer infill types to get some interesting results. Web gyroid infill patterns can significantly improve your 3d prints by removing the necessity of configuring infill orientation to support your model. Different shapes provide different strength characteristics to printed objects. Web the gyroid infill pattern facilitates smooth and consistent filament flow during printing. Find. Web infill pattern refers to the internal structure of the 3d printed part. Grid, rectilinear, honeycomb and cubic. For functional 3d parts, the focus is on strength and resistance to stresses and forces in all directions at the expense. I know there are others, but those 4 are favoured due to their strength and ability to be printed at high. A lot of people love the gyroid pattern because it also looks beautiful, especially when you use transparent filaments because you can see the internal geometry. It’s hard to describe this pattern’s design, but it’s basically a series of squiggly lines that run across the x and y axes of the print bed. Learn about the gyroid infill pattern and. If compressed in the z direction, it's like pressing against carpets. Web an infill pattern can be both aesthetically pleasing and super strong. Web infill pattern refers to the internal structure of the 3d printed part. In fused deposition modeling (fdm) 3d printing, it is common to generate an infill pattern to decrease the density of the 3d printed part.. Triangle, grid and rectilinear are stronger for vertical forces, but gyroid is stronger for horizontal forces. It distributes tension better than angular infill patterns. The gyroid infill is a pattern whose most important feature is its cubic symmetry, which in contrast to all other patterns is an almost isotropic structure, which means that it is equally resistant to forces coming. High shear strength, and ; If you want maximum strength and don’t care about speed, honeycomb patterns may be a better option. The continuous, interconnected channels enable efficient material distribution, reducing the chances of clogs or inconsistent extrusion. It’s one of the few 3d structures that provide great support in every direction. Editing infill doesn’t end with choosing an infill. Web infill pattern refers to the internal structure of the 3d printed part. It’s hard to describe this pattern’s design, but it’s basically a series of squiggly lines that run across the x and y axes of the print bed. Uniform in all orientations), meaning that is very suitable for flexible prints. In fused deposition modeling (fdm) 3d printing, it. The gyroid infill is a pattern whose most important feature is its cubic symmetry, which in contrast to all other patterns is an almost isotropic structure, which means that it is equally resistant to forces coming from all directions. The gyroid pattern was first discovered in 2017 by researchers working with graphene at mit. Web choosing a strong infill pattern. Editing infill doesn’t end with choosing an infill type for the internal parts of the object. Uniform in all orientations), meaning that is very suitable for flexible prints. Web the gyroid infill pattern facilitates smooth and consistent filament flow during printing. Web gyroid has the strongest strength distribution in all directions, meaning no other infill pattern is as strong at. These can be adjusted in the print settings/infill/top (bottom) fill pattern tab. It is strong in all directions without being stiff. The special shape of this infill allows filling it with resin or another liquid. Web gyroid infill alternates between horizontal and vertical directions, meaning there are gaps in the z direction. Web the gyroid infill pattern facilitates smooth and. I know there are others, but those 4 are favoured due to their strength and ability to be printed at high speeds. Editing infill doesn’t end with choosing an infill type for the internal parts of the object. In fused deposition modeling (fdm) 3d printing, it is common to generate an infill pattern to decrease the density of the 3d printed part. On top of these advantages gyroid infill prints relatively fast with respect to some other infill types and is close to isotropic (i.e. It distributes tension better than angular infill patterns. Web the advantages of gyroid infill over the tested infill types are: Web the gyroid infill pattern facilitates smooth and consistent filament flow during printing. Web an infill pattern can be both aesthetically pleasing and super strong. Web gyroid has the strongest strength distribution in all directions, meaning no other infill pattern is as strong at resisting forces in all directions both vertically and horizontally. Web types of top (bottom) layer infill. It’s one of the few 3d structures that provide great support in every direction. Web gyroid 3d print infill is unique since it is a naturally occurring structure found in cell membranes and butterfly wings. A lot of people love the gyroid pattern because it also looks beautiful, especially when you use transparent filaments because you can see the internal geometry. Different shapes provide different strength characteristics to printed objects. Web what is gyroid infill and why is it so great? Web infill pattern refers to the internal structure of the 3d printed part.Best 3D Printing Infill Pattern

The Power of Gyroid Infill in 3D Printing Strength, Efficiency, Preci

a Gyroid infill pattern at 30 infill volume, b triangle infill pattern

3D Printing With Gyroid Infill YouTube

Gyroid infill pattern looks really nice r/3Dprinting

Gyroid Infill Basic Pattern Info for 3D Printing Maker Industry

The Power Of Gyroid Infill In 3D Printing

Gyroid Infill Timelapse 2, created by Chuck Kozlowski YouTube

5 Strongest Infill Patterns Every 3D Print Slicer Should Have

Gyroid infill looks beautiful! prusa3d

Web Gyroid Infill Alternates Between Horizontal And Vertical Directions, Meaning There Are Gaps In The Z Direction.

If Compressed In The Z Direction, It's Like Pressing Against Carpets.

Grid, Rectilinear, Honeycomb And Cubic.

These Can Be Adjusted In The Print Settings/Infill/Top (Bottom) Fill Pattern Tab.

Related Post: