8 Lug Torque Pattern

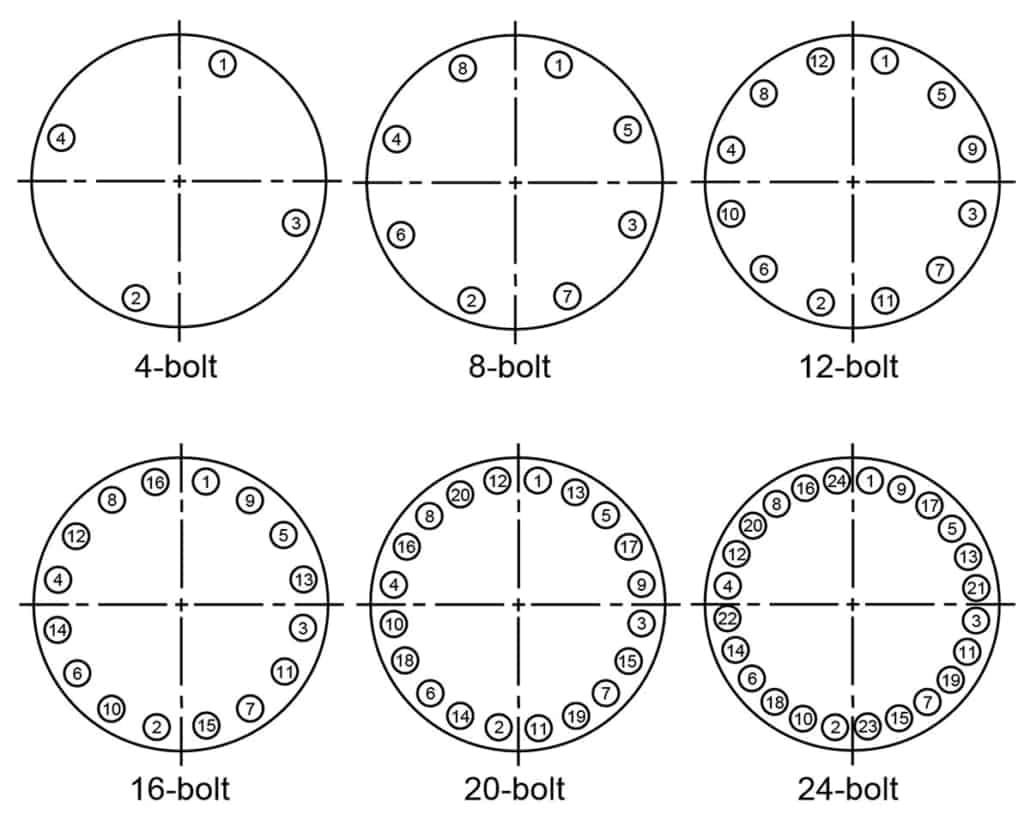

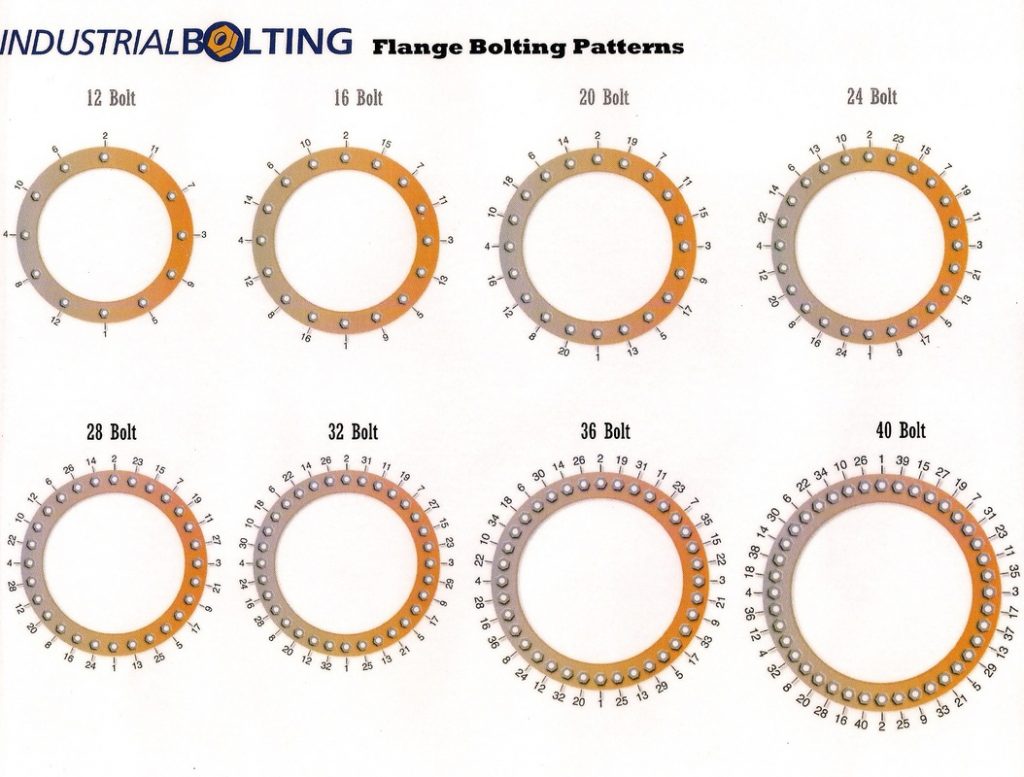

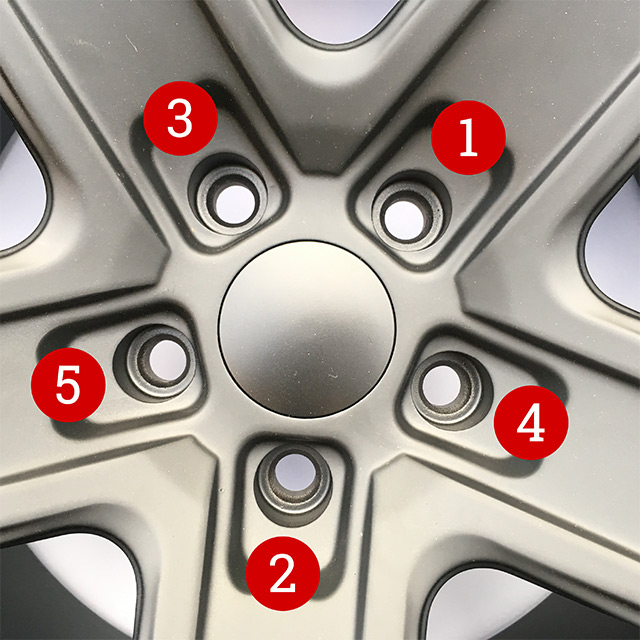

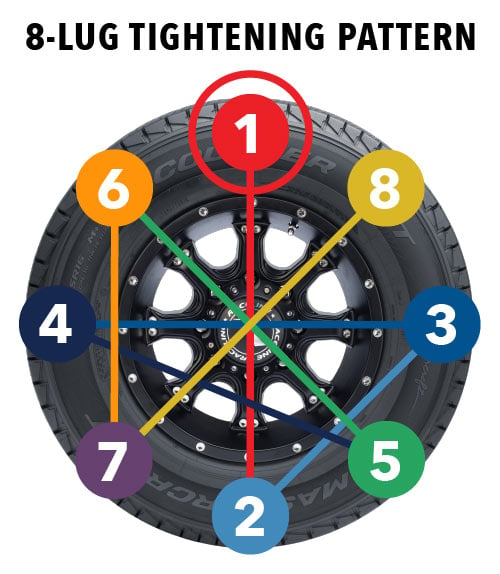

8 Lug Torque Pattern - Common bolt patterns are 4, 5, 6, or 8 lug holes. Just alternate from one side to another like top, bottom, next to top, next to bottom until you make it around the bolt hole circle. Web common bolt patterns have 4, 5, 6, or 8 lug holes, while less common have 3, 7, or 10 lug bolt patterns. Web how to measure bolt pattern. Speedway motors has a precision bolt circle template that simplifies the most common 5 lug patterns for you. Web you need to tighten your lug nuts in the correct order to achieve proper lug nut torque values. Begin with the appropriate bolt for your wheel. The diagrams below indicate the proper measuring methods. Start by hand tightening each nut onto the wheel studs, then use a lug wrench to tighten them further following a star pattern. This pattern helps to evenly distribute the torque and ensures proper wheel alignment. Web the chevy 8 lug bolt pattern is standard for use on the 8×6.5″ bolt patterned wheels. Pcd size, centerbore, offset and wheel dimensions. 65 to 90 ft.lbs, i favor the high side of the spec. Web in order to determine the torque rating for the lug nuts on your trailer you will need to know check out the chart i attached that shows all of the torque specs for all the trailer lugs available based on stud size, wheel material and wheel size. Web how to measure bolt pattern. This diagram will show you what order to tighten your lug nuts. Web what is the 8×180 bolt pattern? This pattern consists of 8 lugs on the front and 6 lugs on the rear. Most domestic trucks have this bolt pattern, but other bolt patterns are available now for trucks like the toyota tacoma and nissan titan. Begin with the appropriate bolt for your wheel. Web to find your bolt pattern, measure the distance as accurately as possible and then find the corresponding bolt pattern in the conversion table below. Web wheel torque sequence chart for wheel nut installation. Web what is the 8×180 bolt pattern? Web how to tighten lug nuts. Begin with the appropriate bolt for your wheel. The bolt pattern or bolt circle is the diameter of an imaginary circle formed by the centers of the wheel lugs. Web how to tighten lug nuts. Finding the proper torque for lug nuts and lug bolts is the first step and can usually be found in the vehicles owner's manual. Web to find your bolt pattern, measure the distance. We recommend using the rist method of lug installation: In simple terms, there are 8 studs on the wheel, arranged in a circular shape. Web how to measure bolt pattern. Finding the proper torque for lug nuts and lug bolts is the first step and can usually be found in the vehicles owner's manual. Web the chevy 8 lug bolt. Common bolt patterns are 4, 5, 6, or 8 lug holes. This involves using a torque wrench to apply the specified amount of force to each lug nut in a star or crisscross pattern. (r) remove debris from mounting surfaces, (i) inspect components for damage or excessive wear, (s) snug the lugs in a star pattern, and (t) torque to. Pcd size, centerbore, offset and wheel dimensions. We recommend using the rist method of lug installation: The 8x180mm or 8×7.08 inch pattern refers to a wheel configuration including 8 stud nuts and a pitch circle diameter of 180 millimeters or 7.08 inches. Web what is the 8×180 bolt pattern? Finding the proper torque for lug nuts and lug bolts is. The 8x180mm or 8×7.08 inch pattern refers to a wheel configuration including 8 stud nuts and a pitch circle diameter of 180 millimeters or 7.08 inches. Pcd size, centerbore, offset and wheel dimensions. Web in order to determine the torque rating for the lug nuts on your trailer you will need to know check out the chart i attached that. Web this ez to read page shows the wheel (lug) torque sequence for bolt 4, 5, 6 and 8 lug patterns. No need to guess any longer! Just alternate from one side to another like top, bottom, next to top, next to bottom until you make it around the bolt hole circle. This pattern consists of 8 lugs on the. Web the chevy 8 lug bolt pattern is standard for use on the 8×6.5″ bolt patterned wheels. Web to find your bolt pattern, measure the distance as accurately as possible and then find the corresponding bolt pattern in the conversion table below. In simple terms, there are 8 studs on the wheel, arranged in a circular shape. Speedway motors has. Speedway motors has a precision bolt circle template that simplifies the most common 5 lug patterns for you. Web this ez to read page shows the wheel (lug) torque sequence for bolt 4, 5, 6 and 8 lug patterns. Just alternate from one side to another like top, bottom, next to top, next to bottom until you make it around. For example, if you have a 5 lug wheel and your measurement is 5 then your bolt pattern is 5 x 5 (5 x 127mm). (12 o’clock position for 8 and 6 hole wheels and 2 o’clock position for 5 hole wheels, as illustrated) and apply torque to all lug nuts following the star pattern indicated. Common bolt patterns are. Web common bolt patterns have 4, 5, 6, or 8 lug holes, while less common have 3, 7, or 10 lug bolt patterns. Finding the proper torque for lug nuts and lug bolts is the first step and can usually be found in the vehicles owner's manual. Web torque the lug nuts in two steps, starting at 40 ft/lbs of torque for your first step to get the wheel seated properly. The 8x180mm or 8×7.08 inch pattern refers to a wheel configuration including 8 stud nuts and a pitch circle diameter of 180 millimeters or 7.08 inches. This involves using a torque wrench to apply the specified amount of force to each lug nut in a star or crisscross pattern. In simple terms, there are 8 studs on the wheel, arranged in a circular shape. This diagram will show you what order to tighten your lug nuts. 65 to 90 ft.lbs, i favor the high side of the spec. Web this ez to read page shows the wheel (lug) torque sequence for bolt 4, 5, 6 and 8 lug patterns. It also has the initials of the person who did it. Each is spaced evenly apart from its neighboring holes. (12 o’clock position for 8 and 6 hole wheels and 2 o’clock position for 5 hole wheels, as illustrated) and apply torque to all lug nuts following the star pattern indicated. Web torquing lug nuts and bolts correctly is a vital part of making sure your tire and wheel assembly rides smoothly, wears evenly and performs as expected. Web in order to determine the torque rating for the lug nuts on your trailer you will need to know check out the chart i attached that shows all of the torque specs for all the trailer lugs available based on stud size, wheel material and wheel size. Begin with the appropriate bolt for your wheel. Web how to tighten lug nuts.Flange Bolt Torque Sequence UIP International Premium Industrial

Wheel Bolt Patterns & Typical Lug Nut Torque Specifications Quadratec

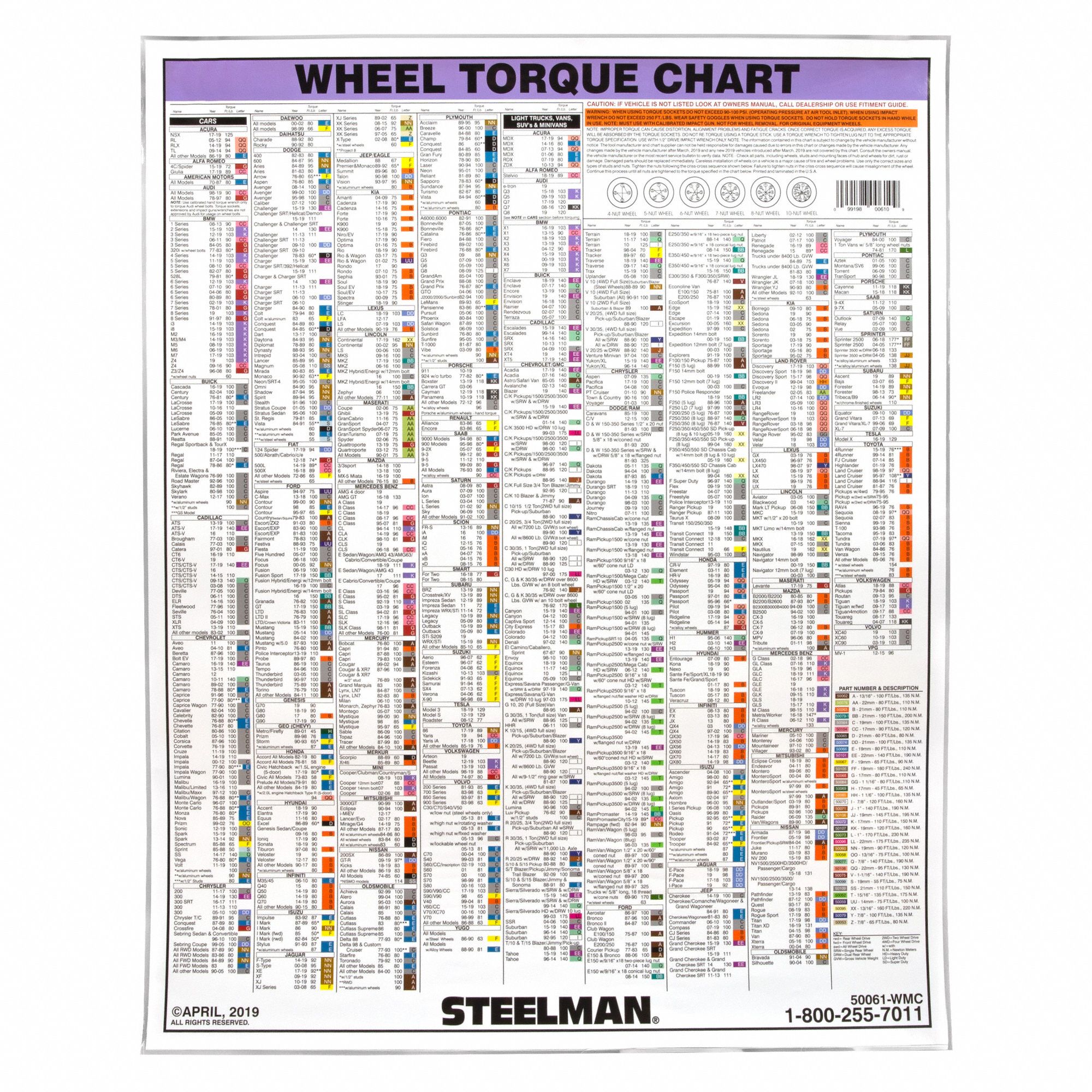

Printable Lug Nut Torque Chart

Torque Charts Industrial Torque Tools

Wheel Lug Torque Sequence GTSparkplugs

Wheel Bolt Patterns & Typical Lug Nut Torque Specifications Quadratec

How to Change a Tire Les Schwab

Torque Values For Mechanical Lugs

Lug Nut Torque Specifications Chart Printable

Mechanical Lug Torque Chart

Most Domestic Trucks Have This Bolt Pattern, But Other Bolt Patterns Are Available Now For Trucks Like The Toyota Tacoma And Nissan Titan.

Web You Need To Tighten Your Lug Nuts In The Correct Order To Achieve Proper Lug Nut Torque Values.

For Example, If You Have A 5 Lug Wheel And Your Measurement Is 5 Then Your Bolt Pattern Is 5 X 5 (5 X 127Mm).

Web The Chevy 8 Lug Bolt Pattern Is Standard For Use On The 8×6.5″ Bolt Patterned Wheels.

Related Post: